The E4 Pro CNC is our most advanced 3-axis machining centre, specifically designed for manufacturers who refuse to compromise on quality. Notably, it combines a massive, heat-stabilized steel chassis with the world’s finest international components. Specifically, it features the flagship OSAI Industrial Controller and a 9 kW HSD Spindle with HSK-63F tooling. Consequently, it delivers unmatched rigidity and “glass-smooth” finishes, even when processing heavy solid wood, thick composites, or high-volume nesting.

Unmatched Precision and Performance The E4 Series represents the pinnacle of our CNC technology. Specifically, we engineered this machine with premium international components to set the highest standards in manufacturing. Unlike lighter machines, the E4 uses a massive, heat-stabilised steel frame. Therefore, it provides the ultimate stability required for heavy architectural joinery and continuous production.

Italian Power & HSD Drilling At its core lies a powerful 9 kW HSD Spindle, manufactured by the Italian world leader in motor technology. Notably, this “Long Nose” version utilises wider bearing spacing. As a result, it significantly reduces vibration and improves rigidity at the tool tip. Furthermore, we integrated an HSD Drill Bank to provide sophisticated drilling capabilities, making the E4 Pro CNC a complete production centre for cabinetry and furniture.

Flagship OSAI Control Precision starts with control; thus, the E4 Pro runs on the advanced OSAI industrial system from Prima Electro. By using the Mechatrolink III protocol, the controller communicates directly with Japanese Yaskawa Servo Motors. Consequently, this closed-loop system delivers pinpoint accuracy. Moreover, Japanese Shimpo gearboxes ensure smooth, precise power transmission during high-speed movements.

World-Class Motion Components We selected every part for longevity. For instance, Japanese THK linear rails guide the motion to ensure exceptional accuracy and minimal friction throughout the machine’s life. Additionally, German Becker vacuum pumps provide powerful and consistent workpiece holding. Finally, the entire system is designed to withstand the most demanding manufacturing environments.

Spindle: 9 kW HSD “Long Nose” (HSK-63F) with integrated Drill Bank.

Controller: Flagship OSAI Industrial System (Italy).

Drive System: Yaskawa Servos with Shimpo Gearboxes (Japan).

Vacuum System: German Becker Pumps.

Motion Hardware: THK Linear Rails (Japan).

Ideal Applications: Architectural Joinery, Heavy Solid Wood, Aerospace Patterns, and High-Volume Manufacturing.

Choosing the right CNC router depends on your material requirements and daily throughput. Notably, while the EK C&D Series provides an exceptional entry point for joinery, the E4 Pro CNC is specifically engineered for high-volume environments requiring maximum rigidity.

EK C&D Series: The ideal for workshops moving away from manual machining.

EK-G High-Speed: Specifically designed for rapid nesting, utilizing a reinforced gantry for faster cycle times. Furthermore, it features an integrated automatic labelling system to eliminate sorting errors and speed up downstream assembly.

E3 Series: A professional-grade solution that bridges the gap with advanced control and standard drilling capabilities.

E4 Pro CNC: Our flagship , featuring a massive heat-stabilized frame and OSAI control for the most demanding applications.

Industrial Construction: Frames and gantries are manufactured from heavy-duty, heat-stabilised steel. This ensures long-term durability and prevents warping. Furthermore, the machine utilises Japanese THK linear guide rails and precision-ground ball screws for exceptional accuracy and minimal friction.

Flagship Control: Powered by the latest OSAI OPEN controller from Prima Electro (Italy). Features a closed-loop servo system communicating via Mechatrolink III to high-torque Japanese Yaskawa motors.

Power & Drilling: Equipped with a 9 kW HSD HSK-63 Spindle (Long Nose) and a dedicated HSD Drill Bank for sophisticated boring operations.

Vacuum Technology: Features a German Becker Vacuum Pump (5.5 kW) with a high-flow double-layer PVC vacuum table. This guarantees powerful workpiece holding for nesting applications.

Advanced Safety & Cleanliness: Includes a robust dust collection system with four integrated blowers to clear debris from the cutting path. Additionally, all cables are high-flex and heat-resistant, enclosed in sealed chains to prevent dust ingress.

Smart Factory Ready: Available with optional automatic loading/unloading tables and sheet labelling systems. Supports remote diagnostics via Ethernet for instant technical support.

Software Package: Vectric Cut 2D Pro is supplied as standard (VCarve/Aspire optional). Can be sold as a complete design-to-manufacture package with Polyboard, StairDesigner, OptiCUT, and OptiNEST.

| ITEM | DESCRIPTION | E4-1224 | E4-1530 | E4-2128 | E4-2030 | E4-2040 | OPTION |

|---|---|---|---|---|---|---|---|

| TRAVELLING AREA | X | 1220 mm | 1525 mm | 2100 mm | 2030 mm | 2030 mm | 3000 mm |

| Y | 2440 mm | 3050 mm | 2800 mm | 3050 mm | 4000 mm | 100000 mm | |

| Z | 180 mm | 180 mm | 180 mm | 180 mm | 180 mm | 400 mm | |

| ACCURACY | WORKING ACCURACY | 0.05 mm | 0.05 mm | 0.05 mm | 0.05 mm | 0.05 mm | |

| REPOSITIONING | 0.05/500 mm | 0.05/500 mm | 0.05/500 mm | 0.05/500 mm | 0.05/500 mm | ||

| STRUCTURE | TABLE | VACUUM MATRIX/PHENOLIC | VACUUM MATRIX/PHENOLIC | VACUUM MATRIX/PHENOLIC | VACUUM MATRIX/PHENOLIC | VACUUM MATRIX/PHENOLIC | DOUBLE LAYER-HIGH FLOW |

| SPEED | TRANSMISSION | HELICAL RACK XY, BALLSCREW Z | HELICAL RACK XY, BALLSCREW Z | HELICAL RACK XY, BALLSCREW Z | HELICAL RACK XY, BALLSCREW Z | HELICAL RACK XY, BALLSCREW Z | |

| MAX RAPID | 50000 mm/min | 50000 mm/min | 50000 mm/min | 50000 mm/min | 50000 mm/min | ||

| MAX FEEDRATE | 25000 mm/min | 25000 mm/min | 25000 mm/min | 25000 mm/min | 25000 mm/min | ||

| SPINDLE | SPINDLE TYPE | HSD 9.0 kW HSK | HSD 9.0 kW HSK | HSD 9.0 kW HSK | HSD 9.0 kW HSK | HSD 9.0 kW HSK | HSD 12.0 kW HSK |

| SPINDLE SPEED | 3000-24000 RPM | 3000-24000 RPM | 3000-24000 RPM | 3000-24000 RPM | 3000-24000 RPM | Drill Bank | |

| DRIVE | SERVO/PLANETARY GEARBOX | SERVO/PLANETARY GEARBOX | SERVO/PLANETARY GEARBOX | SERVO/PLANETARY GEARBOX | SERVO/PLANETARY GEARBOX | ||

| NC CONTROLLER | OSAI OPEN | DIGITAL CLOSED LOOP | DIGITAL CLOSED LOOP | DIGITAL CLOSED LOOP | DIGITAL CLOSED LOOP | DIGITAL CLOSED LOOP | |

| SOFTWARE | VECTRIC | CUT 2D PRO | CUT 2D PRO | CUT 2D PRO | CUT 2D PRO | CUT 2D PRO | ANY |

| COMMAND CODE | ISO G-CODE | ISO G-CODE | ISO G-CODE | ISO G-CODE | ISO G-CODE | ||

| ELECTRICAL | 3-PHASE 400V | 1 X 32A MACHINE MAIN | 1 X 32A MACHINE MAIN | 1 X 32A MACHINE MAIN | 1 X 32A MACHINE MAIN | 1 X 32A MACHINE MAIN | |

| COMPRESSED AIR | CLEAN & DRY | 8CFM @ 7BAR | 8CFM @ 7BAR | 8CFM @ 7BAR | 8CFM @ 7BAR | 8CFM @ 7BAR |

No router is complete without a world-class heart. The E4 Pro CNC utilises the market-leading 9 kW HSD spindle from Italy. Notably, this “Long Nose” version features wider bearing spacing. Consequently, it reduces vibration at the tool tip and improves rigidity. Furthermore, we integrated a sophisticated HSD drill bank, allowing the machine to handle complex cabinet drilling operations with exceptional speed and precision.

Precision requires premium control. The E4 Pro runs on the latest OSAI system from Prima Electro. By using the Mechatrolink III protocol, the controller communicates directly with Japanese Yaskawa Servo Motors. Consequently, this closed-loop system ensures pinpoint accuracy. In addition, Japanese Shimpo gearboxes guarantee smooth power transmission. Ultimately, this combination delivers the reliability needed for high-volume manufacturing.

The E4 Pro CNC is the ultimate high-capacity nesting centre. Uniquely, we can supply it with automatic loading, unloading, and part labelling systems. Moreover, it integrates seamlessly with parametric software like Polyboard and StairDesigner. Therefore, it can function as a standalone unit or part of a complete “Smart Factory” production line. Finally, the heat-stabilised chassis ensures consistent accuracy, even during heavy 24/7 operation.

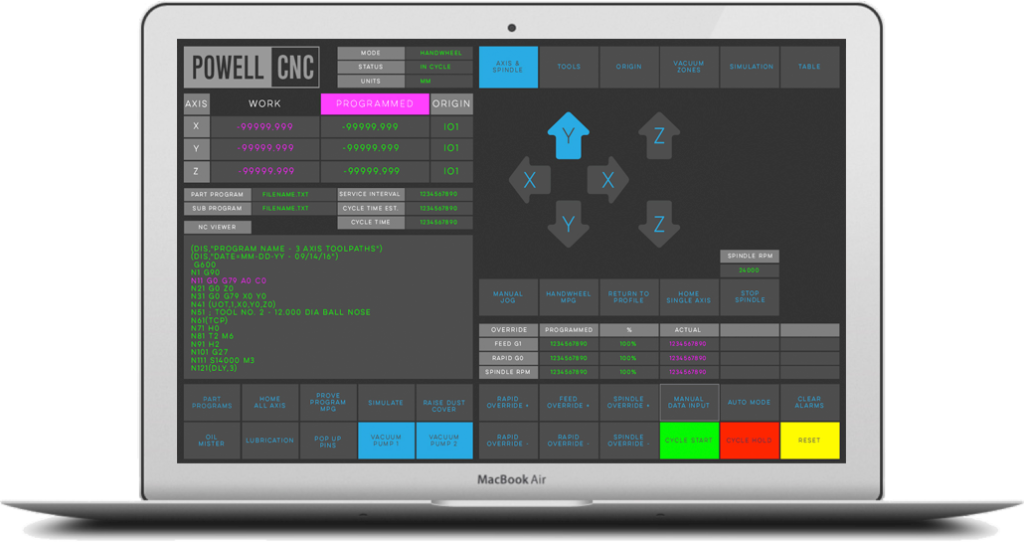

The E4 Pro CNC features an advanced user interface that pairs an industrial-grade touchscreen with a familiar Windows operating environment. Consequently, you can install preferred CAD/CAM packages directly on the console for “at-the-machine” programming. Furthermore, the system supports full integration with industry-leading parametric software like Polyboard and StairDesigner. Finally, the high-speed Ethernet connection ensures you can manage production files seamlessly from your office network.

Please fill out the form below to request a brochure

Please fill out the form below to request finance*

Please fill out the form below to raise a ticket with our support team