The E3 Pro is the definition of industrial versatility. Engineered for high-speed performance in the toughest materials, it utilizes class-leading components for 24/7 manufacturing.

Powered by the premium Italian OSAI Controller and a 9.5kW HSD Spindle, the E3 Pro delivers “Zero-Vibration” machining whether you are processing solid wood, aerospace plastics, or composite panels. With a 16-position rotary tool changer and heat-stabilised steel frame, it is built to run all day, every day.

We designed the E3 Pro CNC router to meet the highest standards of precision and efficiency. Unlike standard routers, the E3 Pro features a heat-stabilised steel frame with heavy-duty gantries. Consequently, this construction ensures longevity and consistent performance, even under heavy production loads.

At its core lies a 9.5kW HSD Spindle (Italian World Leader). Specifically, this “Long Nose” version features wider bearing spacing. As a result, it reduces vibration and improves rigidity at the tool tip. Crucially, it utilises the HSK Clamping System. This system is vastly superior to standard ISO-30 holders. Therefore, it ensures a tighter grip and better finish quality at high speeds.

The state-of-the-art OSAI OPEN digital NC control system drives the E3 Pro. By handling the servo loop over EtherCAT, it communicates directly with Japanese Yaskawa Servo Motors via Mechatrolink III. This combination delivers unrivalled accuracy and response. Furthermore, this closed-loop system allows for pinpoint precision, even when cutting 20mm thick materials in a single pass at speeds up to 25m/min.

We selected every component for maximum durability. For instance, the machine features German Becker vacuum pumps (250 m³/hr) with an integrated high-flow phenolic matrix table. This ensures maximum hold-down power. Additionally, sealed chains protect all wiring to prevent dust ingress. Finally, we use high-quality IGUS cables, which we tested to withstand over 10 million bends.

ATC System: 16-position rotary changer for reduced non-cutting time.

Motion: German precision-ground helical rack and pinion.

Spindle: 9.5kW HSD Air Cooled (HSK-63F).

Vacuum: Becker Oilless Rotary Vane Pumps.

Efficiency: Automatic material alignment with pop-up location pins.

Ideal For: Complex Cabinetry, Precision Manufacturing, Solid Wood, & Plastic Fabrication.

Choosing the right CNC router depends on your material requirements and daily throughput. Notably, while the EK C&D Series provides an exceptional entry point for joinery, the E4 Pro CNC is specifically engineered for high-volume environments requiring maximum rigidity.

EK C&D Series: The ideal for workshops moving away from manual machining.

EK-G High-Speed: Specifically designed for rapid nesting, utilizing a reinforced gantry for faster cycle times. Furthermore, it features an integrated automatic labelling system to eliminate sorting errors and speed up downstream assembly.

E3 Series: A professional-grade solution that bridges the gap with advanced control and standard drilling capabilities.

E4 Pro CNC: Our flagship , featuring a massive heat-stabilized frame and OSAI control for the most demanding applications.

Heat-Stabilised Steel Construction: All frames and gantries are manufactured from heat-stabilised steel to ensure longevity and consistent performance, even during heavy 24/7 processing.

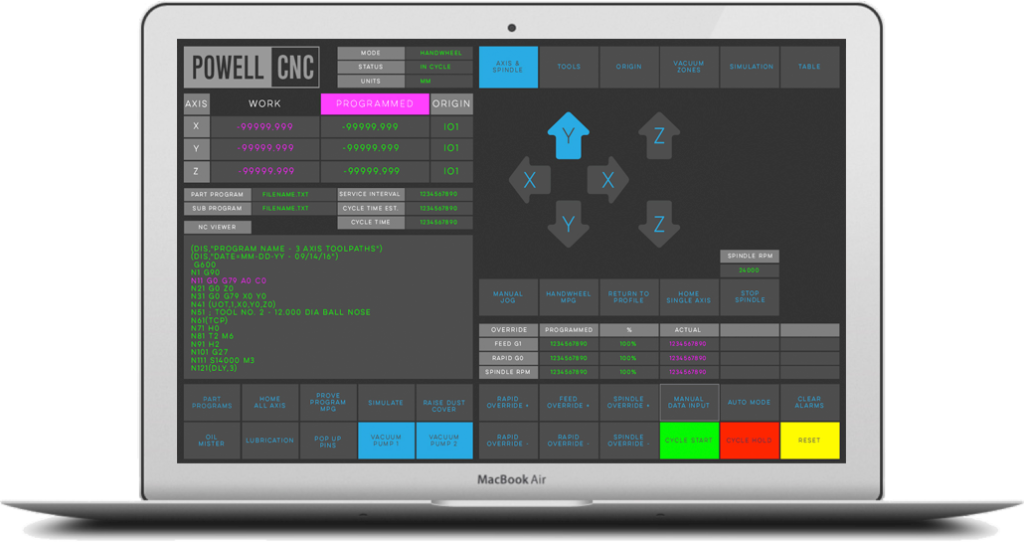

Flagship OSAI Control: Powered by the latest generation Italian OSAI OPEN controller. Features a user-friendly touchscreen interface running in a Windows environment, allowing for easy integration into your company network.

German Becker Vacuum Technology: Equipped with the highest quality Becker Vacuum Pumps and oversized 85mm manifolds for optimum workpiece holding. The double-layer phenolic high-flow deck ensures perfect flatness even in fluctuating temperatures.

Precision Motion & Drive: State-of-the-art digital drivers and servo motors deliver pinpoint control and accuracy. All wiring is protected by German Igus cables and sealed chains for hassle-free, long-life processing.

High-Speed ATC: Features a flexible 8-16 position rotary tool changer for maximum efficiency.

Smart Features: Includes Pop-Up Material Location Pins for fast loading and Remote Diagnostics via Ethernet for instant support and training.

Industry-Leading Software: Vectric Cut 2D Pro is supplied as standard (with VCarve or Aspire upgrades available). Can be supplied as a complete “Design-to-Manufacture” package with Polyboard, StairDesigner, OptiCUT, and OptiNEST.

| ITEM | DESCRIPTION | E3-1325 | E3-1525 | E3-1530 | E3-2030 | E3-2040 | OPTION |

|---|---|---|---|---|---|---|---|

| TRAVELLING AREA | X | 1260 mm | 1525 mm | 1525 mm | 2030 mm | 2030 mm | 3000 mm |

| Y | 2500 mm | 2500 mm | 3050 mm | 3050 mm | 4000 mm | 100000 mm | |

| Z | 180 mm | 180 mm | 180 mm | 180 mm | 180 mm | 750 mm | |

| ACCURACY | WORKING ACCURACY | 0.05 mm | 0.05 mm | 0.05 mm | 0.05 mm | 0.05 mm | |

| REPOSITIONING | 0.05/500 mm | 0.05/500 mm | 0.05/500 mm | 0.05/500 mm | 0.05/500 mm | ||

| STRUCTURE | TABLE | VACUUM MATRIX/PHENOLIC | VACUUM MATRIX/PHENOLIC | VACUUM MATRIX/PHENOLIC | VACUUM MATRIX/PHENOLIC | VACUUM MATRIX/PHENOLIC | DOUBLE LAYER-HIGH FLOW |

| TRANSMISSION | HELICAL RACK XY, BALLSCREW Z | HELICAL RACK XY, BALLSCREW Z | HELICAL RACK XY, BALLSCREW Z | HELICAL RACK XY, BALLSCREW Z | HELICAL RACK XY, BALLSCREW Z | ||

| SPEED | MAX RAPID | 50000 mm/min | 50000 mm/min | 50000 mm/min | 50000 mm/min | 50000 mm/min | |

| MAX FEEDRATE | 25000 mm/min | 25000 mm/min | 25000 mm/min | 25000 mm/min | 25000 mm/min | ||

| SPINDLE TYPE | HSD 9.0 kW HSK | HSD 9.0 kW HSK | HSD 9.0 kW HSK | HSD 9.0 kW HSK | HSD 9.0 kW HSK | HSD 12.0 kW HSK | |

| SPINDLE | SPINDLE SPEED | 3000-24000 RPM | 3000-24000 RPM | 3000-24000 RPM | 3000-24000 RPM | 3000-24000 RPM | |

| DRIVE | SERVO/PLANETARY GEARBOX | SERVO/PLANETARY GEARBOX | SERVO/PLANETARY GEARBOX | SERVO/PLANETARY GEARBOX | SERVO/PLANETARY GEARBOX | ||

| NC CONTROLLER | OSAI OPEN | DIGITAL CLOSED LOOP | DIGITAL CLOSED LOOP | DIGITAL CLOSED LOOP | DIGITAL CLOSED LOOP | DIGITAL CLOSED LOOP | |

| SOFTWARE | VECTRIC | CUT 2D PRO | CUT 2D PRO | CUT 2D PRO | CUT 2D PRO | CUT 2D PRO | ANY |

| COMMAND CODE | ISO G-CODE | ISO G-CODE | ISO G-CODE | ISO G-CODE | ISO G-CODE | ||

| ELECTRICAL | 3-PHASE 400V | 1 X 32A MACHINE MAIN | 1 X 32A MACHINE MAIN | 1 X 32A MACHINE MAIN | 1 X 32A MACHINE MAIN | 1 X 32A MACHINE MAIN | |

| COMPRESSED AIR | CLEAN & DRY | 8CFM @ 7BAR | 8CFM @ 7BAR | 8CFM @ 7BAR | 8CFM @ 7BAR | 8CFM @ 7BAR |

No router is complete without a world-class heart. We use the premium “Long Nose” HSD spindle from Italy. Its wider bearing spacing eliminates vibration at the tool tip, delivering a superior edge finish and extended tool life compared to standard motors.

Precision requires premium control. The Italian OSAI Open controller uses a digital closed-loop system (Mechatrolink III) to drive high-torque Yaskawa servos. This ensures absolute positioning accuracy and “look-ahead” smooth motion, even during high-speed directional changes.

Superior to standard ISO-30 holders. The HSK interface clamps from the inside, utilizing centrifugal force to grip the tool tighter as the spindle speeds up. This provides the ultimate rigidity needed for heavy profiling and high-speed nesting without tool chatter.

The E3 Pro CNC features an enhanced user interface design, supplemented with industrial grade touch screen for the ultimate user experience. Delivered in a Windows environment the E3 Pro CNC can be installed with all your latest CAD/CAM packages for “at the machine programming” or offline via Ethernet.

Please fill out the form below to request a brochure

Please fill out the form below to request finance*

Please fill out the form below to raise a ticket with our support team